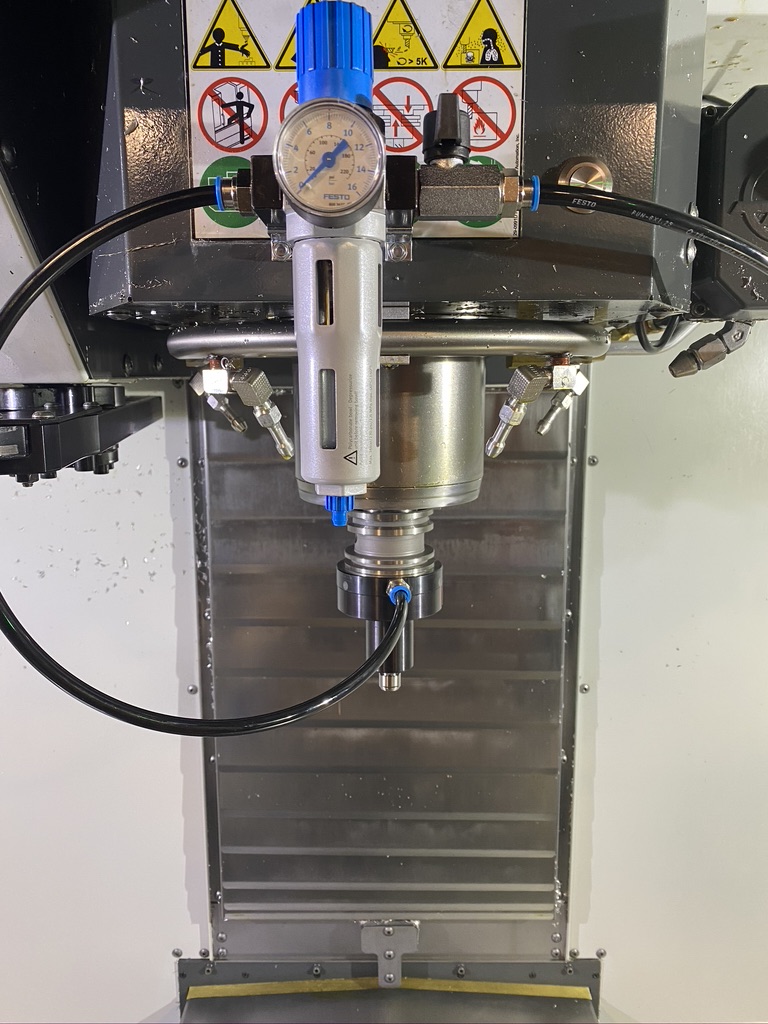

High-speed spindle

CNC machining with a high-speed spindle is a specialized method of manufacturing heatsinks with high precision and accuracy. Here are some benefits of using a high-speed spindle for heatsink applications.

1. High Precision: CNC machining with a high-speed spindle offers high precision and accuracy, allowing for the creation of intricate heatsink designs with tight tolerances.

2. Fast and Efficient: High-speed spindles are designed to operate at high speeds, allowing for faster and more efficient heatsink production.

3. Versatility: CNC machining with a high-speed spindle can manufacture a wide range of heatsinks, including complex shapes and profiles.

4. Quality Control: CNC machining with a high-speed spindle has built-in quality control features, ensuring that each heatsink produced meets the required specifications.

5. Customization: CNC machining with a high-speed spindle can be customized to meet specific heatsink manufacturing requirements, including material selection, size, and shape.

6. Automation: CNC machining with a high-speed spindle is highly automated, reducing the need for manual labor and increasing efficiency.

CNC machining with a high-speed spindle is an excellent choice for heatsink manufacturing, offering high precision, speed, versatility, quality control, customization, and automation. It is widely used in various industries, including electronics, automotive, and aerospace, where high-performance heatsinks are required to dissipate heat efficiently.

Contact us

CALL US TODAY FOR A FAST FREE QUOTE: 925.292.1293.